Ferroalloy nucleating agents are materials used to enhance the crystallization process in alloys. By accelerating the nucleation process, these agents help produce alloys with finer grain structures and improved mechanical properties. In metallurgy, nucleating agents play a key role in enhancing the quality and performance of steel and other alloys

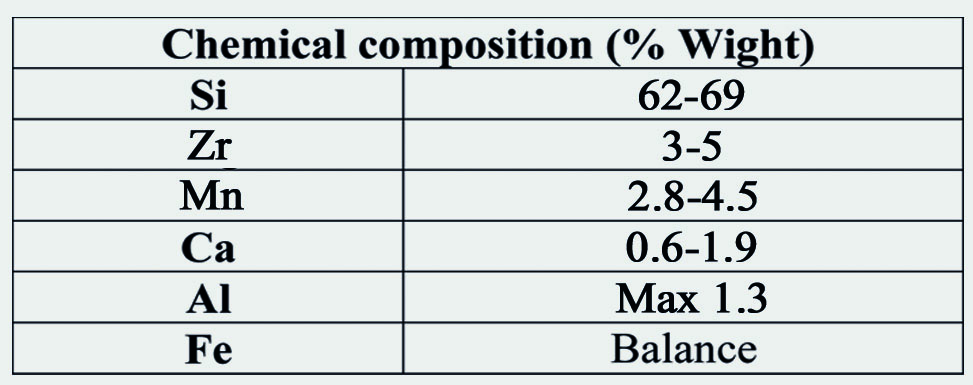

Zirconium-based inoculant is widely used in foundries as a ladle addition or during the pouring stream. It promotes uniform solidification and improves graphite morphology, especially in grey cast irons. This zirconium inoculant is a silicon-based ferroalloy that contains precise and controlled amounts of active elements such as zirconium, calcium, manganese, and aluminum.

Applications:

Stronger than conventional ferrosilicon-based inoculants

Increases the number of nodules and reduces chill

Provides good nodule structure in heavy-section ferritic ductile iron

Grain Size:

0.2 – 0.7 mm / 2 – 6 mm

Packaging:

20 kg bags inside big bags or on pallets

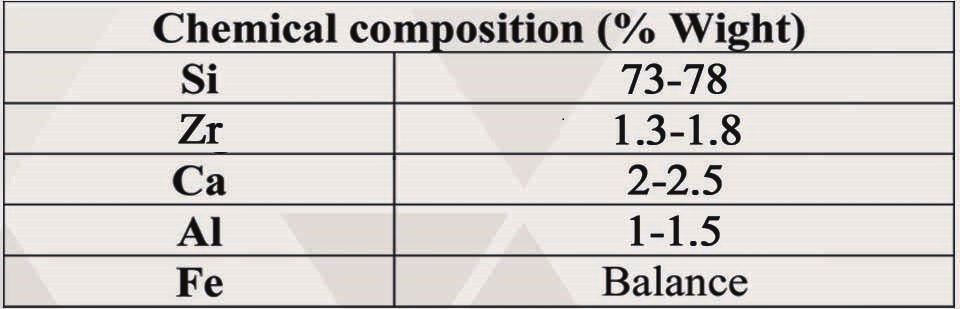

Zirconium-based inoculant is widely used in foundries as a ladle addition or during the pouring stream. It promotes uniform solidification and improves graphite morphology, particularly in grey cast iron. This zirconium inoculant is a silicon-based ferroalloy containing precise and controlled amounts of active elements such as zirconium, calcium, manganese, and aluminum.

Applications:

Stronger than conventional ferrosilicon-based inoculants

Increases nodule count and reduces chill depth

Provides excellent nodule structure in heavy-section ferritic ductile iron

Grain Size:

0.2 – 0.7 mm / 2 – 6 mm

Packaging:

25 kg bags in big bags or on pallets